-

Customizable sisal buffing wheels ,polishing waxes and cotton polishing wheels

Customizable sisal buffing wheels ,polishing waxes and cotton polishing wheels -

Nylon fiber polishing wheels non-woven buffing wheels

Nylon fiber polishing wheels non-woven buffing wheels -

we are selling all kind of abrasive products

we are selling all kind of abrasive products

Please contact us about shipping cost,quantity discount or customized products

Features:

1. The dust suction device and explosion-proof device have been tested by professional organizations to meet environmental protection requirements.

2. The cleaning device is filtered through two processes, which is easy to clean.

3. Stainless steel housing device prevents rust and improves corrosion resistance.

4. Wet dust-proof, prevent dust, ensure a comfortable working environment, and ensure the safety of operators.

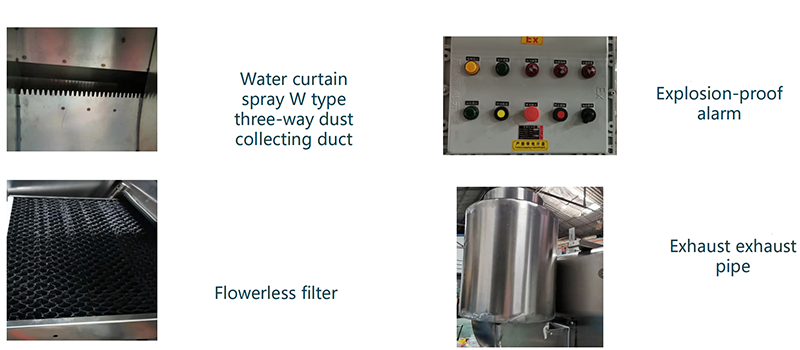

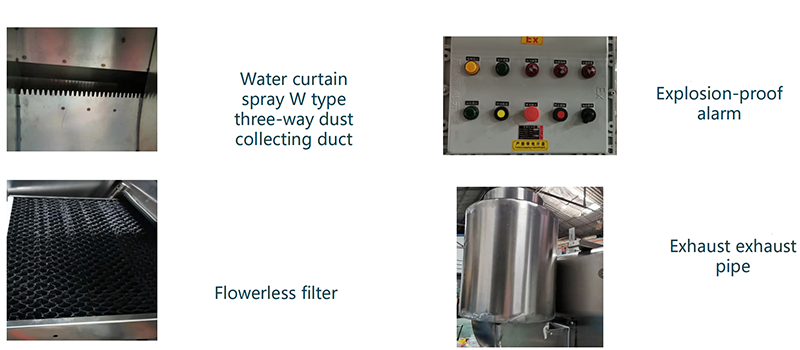

Wet-type explosion-proof and dust-proof polishing machine, the dust gas generated during the polishing and polishing process is attracted by the fan through the dust suction device, and the dust-containing exhaust gas waste passes through the pipe and enters the water curtain spray W type three-way dust collecting air duct. It is the first-stage filtration and enters the flowerless filter. This is the second-stage filtration. With the centrifugal action of the high-efficiency energy-saving fan and the double-action flushing and washing of high-pressure water, the explosive dust gas has been completely removed, and the explosion-proof control cabinet (flammable Electrical equipment for dusty environments), explosion-proof warning lights and other components provide early warning and protection to meet the requirements of explosion-proof standards.

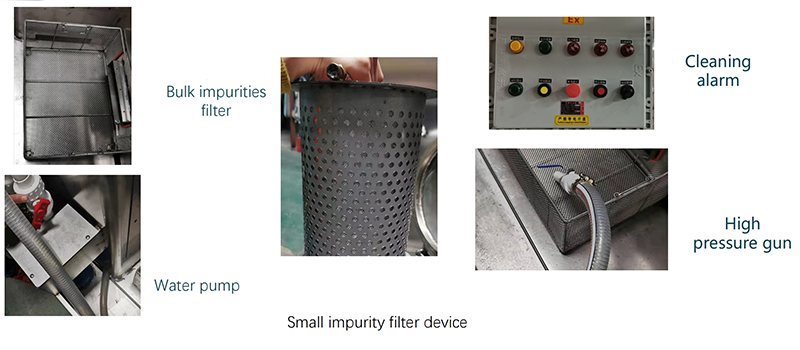

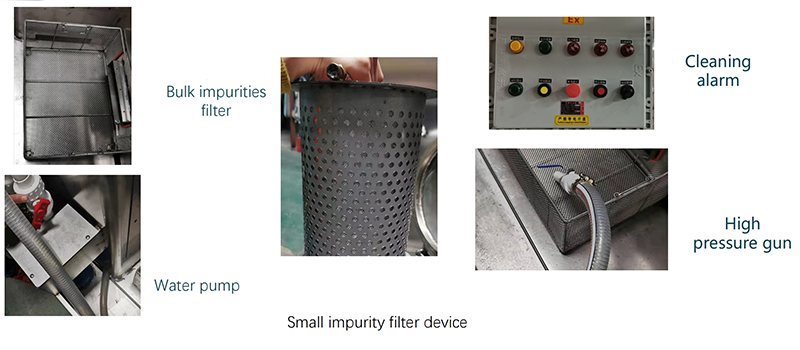

The filtered waste water passes through the first filter screen to filter out large debris, and then passes through the pump to enter the second fine filter screen (the water after the first filter is not easy to block the pump). Smaller particulate impurities are filtered out, and after two water filtrations, most of the discharged waste water has been removed from impurities. The first and second screens can be removed and flushed with a high-pressure water gun equipped with the equipment. The pressure gun improves the convenience of cleaning by the operator. The equipment is equipped with a filter pressure gauge. When the impurity reaches a certain amount, the pressure gauge will alarm to remind the operator to clean the filter device.

Features:

1. The dust suction device and explosion-proof device have been tested by professional organizations to meet environmental protection requirements.

2. The cleaning device is filtered through two processes, which is easy to clean.

3. Stainless steel housing device prevents rust and improves corrosion resistance.

4. Wet dust-proof, prevent dust, ensure a comfortable working environment, and ensure the safety of operators.

Wet-type explosion-proof and dust-proof polishing machine, the dust gas generated during the polishing and polishing process is attracted by the fan through the dust suction device, and the dust-containing exhaust gas waste passes through the pipe and enters the water curtain spray W type three-way dust collecting air duct. It is the first-stage filtration and enters the flowerless filter. This is the second-stage filtration. With the centrifugal action of the high-efficiency energy-saving fan and the double-action flushing and washing of high-pressure water, the explosive dust gas has been completely removed, and the explosion-proof control cabinet (flammable Electrical equipment for dusty environments), explosion-proof warning lights and other components provide early warning and protection to meet the requirements of explosion-proof standards.

The filtered waste water passes through the first filter screen to filter out large debris, and then passes through the pump to enter the second fine filter screen (the water after the first filter is not easy to block the pump). Smaller particulate impurities are filtered out, and after two water filtrations, most of the discharged waste water has been removed from impurities. The first and second screens can be removed and flushed with a high-pressure water gun equipped with the equipment. The pressure gun improves the convenience of cleaning by the operator. The equipment is equipped with a filter pressure gauge. When the impurity reaches a certain amount, the pressure gauge will alarm to remind the operator to clean the filter device.