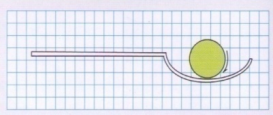

It is mainly used for the inward curve of the spoon where the spoon is thrown. When the spoon is formed, because the inward bending part of the spoon uses the rolling squeezing force, it is easy to cause the phenomenon of wrinkles in the inward bending part of the spoon. Use the inner bending machine, because the pressure of the axle wheel is relatively small, and the efficiency is slow.

Specific matching materials: purple wax, hemp wheel

Process: Scatter the edge and center of the concave part of the spoon (picture: A, B, C, D, E): 5 processes: ordinary hemp wheel + purple wax

Machine: 5

Reason: Because the hardness of the stainless steel material of the spoon is hard, the grinding wheel must have a lot of pressure to polish and cut the surface of the workpiece. And because the inward bending area of the spoon is small and the stress surface is uneven, the concave surface must be divided into 5 The small parts are polished separately (as shown in Figure A, B, C, D), and one surface corresponds to one machine. The smaller the size of the spoon, the smaller the grinding wheel, and the smaller the grinding wheel shaft. The pressure is reduced, and the time required for a grinding process is correspondingly increased, so the overall production efficiency is greatly reduced. Therefore, to ensure production efficiency, an assembly line with 5 machines should be used. (The middle tossing of this noodle is the most troublesome in the whole spoon polishing. After tossing the noodles in the next process, there is no need to toss them separately.)